Glue free wadding has been accepted by more and more consumers for its environmental protection and safety. It is widely used in bedding, mattress, sofa and other soft filling, bra, baby products and other fields, so the glue free wadding production line is widely popular in the field of textile machinery.

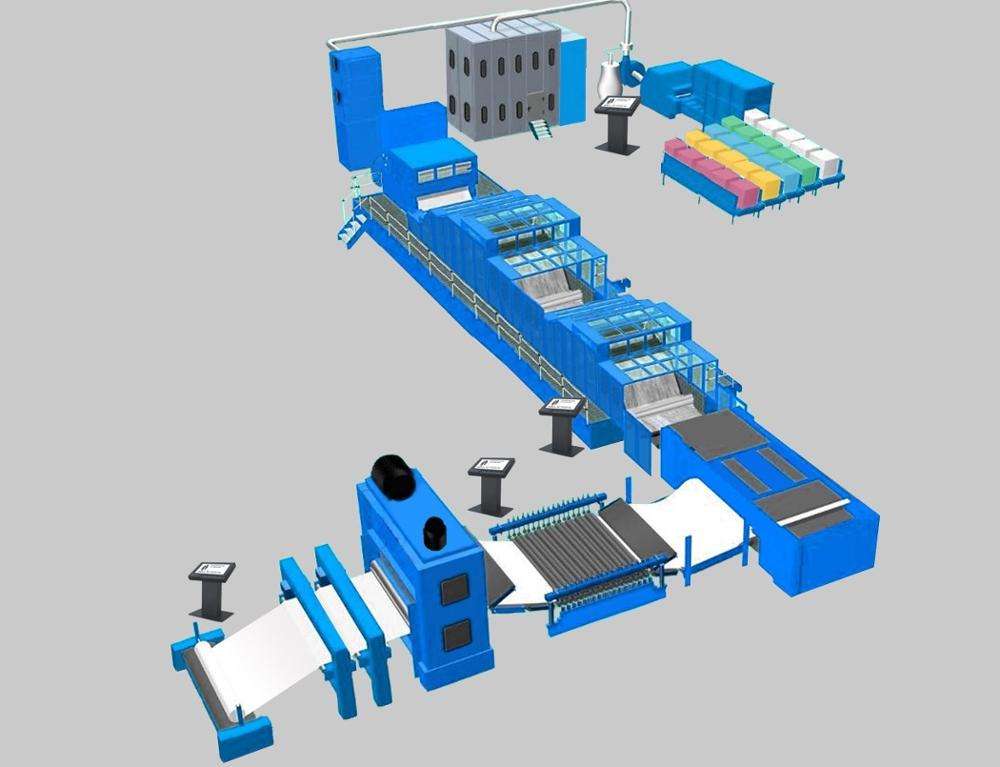

Figure 1: Schematic diagram of the glue free wadding nonwoven production line

Production process of glue free wadding Nonwoven share with you: YOUTUBE VIDEO LINK

Cotton mixing: ratio of all kinds of fiber, mixed fiber.

Initial opening: the mixed raw materials are transported to the pre-opening machine for preliminary opening and fine opening.

Fine opening: the fiber raw materials planned by the pre-opening machine are carefully opened here, so that the crimped fibers are all stretched out for carding.

Cotton collection: the air duct will be fine loose raw materials transported to the cotton collection machine, here after the loose raw materials fluffy soft, also known as doll cotton.

Carding: The cotton collecting machine will send the fine and loose doll cotton into the carding machine, and the fiber will be carded into a network by the carding machine.

Net laying: the cotton after carding is laid into the specified width and thickness according to the parameters, and enters the high needling machine.

Hot pressing: paved cotton mesh is pressed into the specified thickness according to the specified parameters, at the same time, the fiber is initially finalized, into the oven, so far the hot pressing is completed, because of the hot pressing process named hot pressing cotton, hot air cotton, etc.

Finalize the design: after hot pressing fiber here according to the specified parameters after high temperature sterilization pressed into the specified thickness.

Edge cutting: according to the specified parameters will be cut into the specified width or flake specifications, packaging goods, production completed.

Figure 2: Glue free wadding nonwoven production line

TONGDA Glue Free Wadding Nonwoven Production Line:

1.TDL-HY THERMAL-BONDED WADDING PRODUCTION LINE

2.TDL-GL FILTER PRODUCTION LINE

3.TDL-FZ FORMED FELT PRODUCTION LINE

( Read More : Ring Spinning : Definition, Process , Main Operations )

( Read More : How does rotor spinning work? Principle. Operation. Application)

LANGUAGE

LANGUAGE