The compact spinning system assists in producing yarn with a superior finish, significantly reducing hairiness, improving yarn strength, and requiring less raw material to produce yarns of the same quality as traditional spinning systems.

Compact spinning system

main feature :

The compact spinning system assists in producing yarn with a superior finish, significantly reducing hairiness, improving yarn strength, and requiring less raw material to produce yarns of the same quality as traditional spinning systems.

Product details

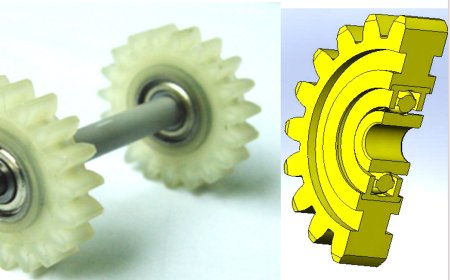

Gearbox parts on top arm

There is no need to change the existing parts on Top Arms, only need to add our compact spinning parts on ring frame drafting system like gearbox, fixing nip and flake.

Gearbox structure

Gearbox with Accotex rubber cots, the drafting ratio can be adjusted to meet the requirments of spinning various fibers.

19T Middle gear in gearbox

Equipped with designed Rolling Bearing of intermediate gear-set of gearbox, this has prolonged the service life.

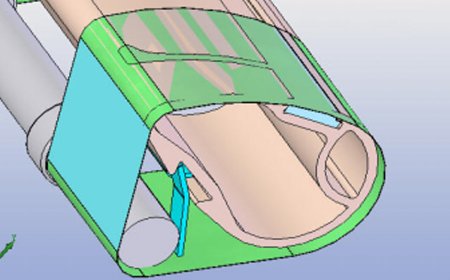

Negative pressure tube adopts super high precision processing technic, long service life, high precision, easy use & maintenance magnetic connection: prevent fibers from suctioning by negative pressure

4.Tension bar, wide radius of curvature, gives tension to aprons for more smooth running so that prolong its lifetime. It is easy to assemble and maintain the tension bar

Special suction slot

Suction flute parts

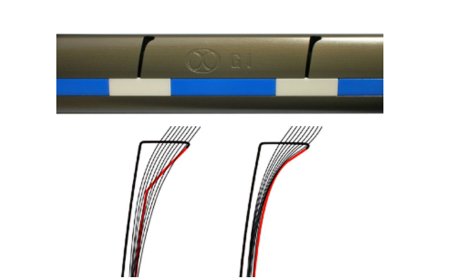

Holes are evenly arrayed on the circumferential surface per square centimeter. It eliminates the uneven periodicity of mesh array by warp & weft weave structure. The soft & elastic apron surface is good for yarn transmission, helping achieve high yarn quality.

Antistatic apron

8.Its main function is to fix negative tube and suction flute as the base of drafting system parts. It is with high precision and consistency when batch processing. Easy erection demanding can assure you of spinning high quality yarn.

Inquiry Now

Start typing and press Enter to search