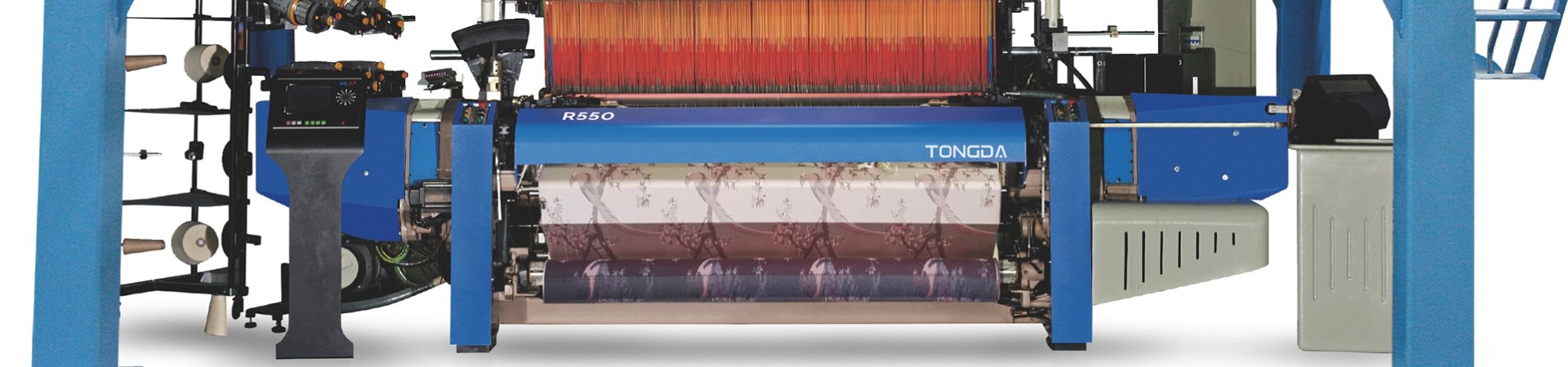

High Speed Rapier Loom R550 is suitable for weaving cotton, wool, linen, chemical fiber, blended fabric;

It is directly driven by PMSM super servo motor, simplity the loom transmission,with all international mainstream loom function, we put the beating up structure at the two side of loom frame.which can strengthen the rigidity of beating up and increase the bealing up force. lt become more easier in connection between heald frame and dobby link rod. When changing the patter.hedde frame can be moved quickly, energy-saving, high efficiency, low failure rate, intelligentization, modularizaion, and continuty.

LANGUAGE

LANGUAGE